Forest Growers Newsletter – December 2021

Improved Log Load Securing

As part of the FGR programme in Automation and Robotics, a project has commenced to develop a safe and efficient alternative load securing system for logging trucks.

Many logging truck drivers suffer musculo-skeletal injuries that are caused by throwing chains over the load and then manually tensioning the load restraints (Figure 1). An improved method of load restraint is required so this project is aimed at developing ways to automate chain throwing and tensioning.

In addition, as debarking in the forest becomes more common, there will be changes to the loads the trucks will be carrying with more debarked logs could be carted from the forest to the port. So, the industry must also consider any changes that may be required to current methods of load restraint to adequately restrain these more slippery debarked logs on logging trucks.

To date, the automatic chain thrower is well advanced with two trucking companies having developed working prototypes for field testing. In addition, two forestry companies have also built machines that lift all the chains over the load simultaneously (Figure 2). These machines are proving effective for use in log yards.

The project will develop a system whereby:

- the chains are automatically thrown over the load.

- the chain tensioning is automatically done by winches that are driven off the truck’s auxiliary power system.

- chain tension will be monitored automatically and if any load settling during the journey is detected the winches will automatically retention the chains without any intervention by the driver.

- the status of the chain tension will be displayed on an in-cab system that will notify the driver if any corrective action is required.

This project is being undertaken with support of the Log Transport Safety Council, in conjunction with Trinder Engineers Ltd of Nelson.

These developments implemented across the NZ logging truck fleet should reduce driver injuries due to chain throwing and tensioning and result in longer driver retention in the industry, and safer log transport, a win for the whole industry.

Pictures 1 & 2 : Manual chain throwing and chain tensioning Picture 3: The automatic chain lifter developed by Timberlands Ltd for use in the log yard

FGR acknowledges co-funding in this project from Ministry for Primary Industries

High performance LVL using non-durable Eucalypts

Laminated veneer lumber (LVL) has successfully been produced in a commercial radiata pine mill (JNL Wairarapa) using veneers from 23-year-old Eucalyptus fastigata. The veneers were glued successfully using one of the glue formulations commercially used by the mill, to produce 24 LVL panels (1.2 x 2.4m), 40mm thick. Image below shows the veneer infeed (colour coded by log/stiffness grade). Following manufacture, the veneers were tested for tension, bending, compression and rail shear strength. All strength and stiffness data were analysed in accordance with the recognised standards.

Mechanical testing of the LVL found that:

- The 95×40 E. fastigata LVL overall achieved the LVL 13 grade as limited by bending stiffness, with the other strength properties meeting or exceeding the highest LVL16 grade.

- Accurate measurement of veneer stiffness was found to be a very good predictor of final bending stiffness but not that reliable in predicting the strength properties.

- It is estimated that the LVL would produce 30% LVL16 and 70% LVL13. This compares with Radiata pine LVL commonly falling into LVL8, 10, 11 & 13 grades.

A full report of this study can be found on the FGR website

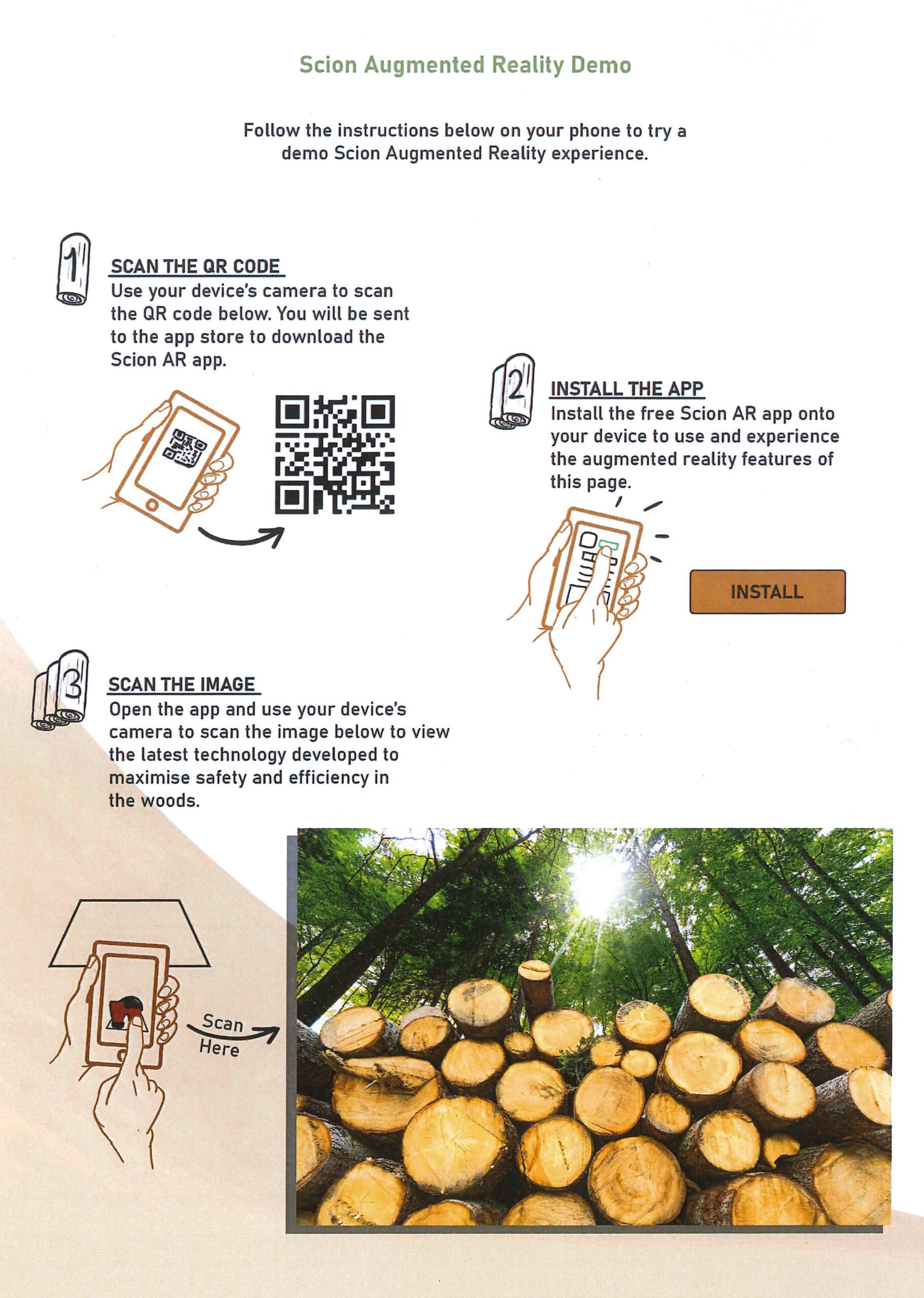

Augmented Reality App

As part of the Human Factors of Automation programme at FGR, Scion has been collaborating with Waratah NZ Ltd, manufacturers of the Waratah range of processor and harvester heads, and Staples VR, a creative technology leader in augmented reality (AR) to develop an in-field servicing tool using AR.

Mechanised harvesting heads are sophisticated pieces of equipment and must be maintained to very exacting specifications. Failure to do this can result in damage to the head, downtime, and lost productivity. Instead of using a paper-based field service manual, operators can now use an augmented reality ‘app’ on a tablet or mobile phone to undertake in-field servicing. The app provides a detailed “walk around” view of the head, and guides the user through safety information, fault reporting, training, maintenance, and service tasks. This app could become an essential and practical tool for harvester head service and maintenance. For a demo of the app, scan the QR code below, install the app, and scan the image below to view the AR in-field servicing tool.

FGR acknowledges co-funding in this project from Ministry for Primary Industries

Annual Report

Annual Report

In September this year FGR published its bi-annual research report. This report provides a high-level overview of the outcomes and activities managed by FGR on behalf of FGLT and Forest Growers. The report includes research that explores some of the existential risks facing forestry, such as the potential impact from disease, reliance on chemical use, and abiotic risks such as fires, floods and droughts. The report also highlights that the New Zealand forest industry continues to embrace the challenges of improving forest value, creating added-value products, meeting environmental targets and modernising operating practices. Through its close links with industry, the forest research sector plays a key role in keeping forest growers on the front foot and enabling pro-active responses to the challenges that arise. The industry’s vision to be New Zealand’s number one primary sector requires a mix of aspirational and applied research as well as support from co-investors, particularly government. The support of the Forest Growers Levy Trust, forest owners, and other research funders is enabling forest growing research to make an increasingly important contribution to the forestry sector. If you are interested in reading more, a copy of the bi-annual report can be found on the FGR website.

Annual Forest Growers Conference

In early September, Covid forced FGR to make the difficult decision to convert our annual conference to webinar format. In hindsight it was the right call to make, and as difficult as it was not to be able to enjoy the social aspects of our annual event, we felt it was more important to promote the exciting research being performed on behalf of our sector, rather than risk not being about to hold an event at all. As with the 2020 event, we saw a surge in participation with over 330 unique registrations, which represents an increase of nearly 40% over 2020 and nearly 3X what we would typically expect at an in-person event. Feedback from the event was very positive with many attendees enjoying the flexibility of the online format as well as the diverse and relevant content. Topics ranged from our large co-funded programmes, such as Automation and Robotics, Specialty Woods Partnership and Resilient Forests, through to strategic organizational overviews, applied climate change work and novel tree nutrition science. To ensure those that may not have been able to attend the event are still about to listen to the presentations, we have loaded all of the sessions onto YouTube. These can be accessed simply by going to the FGR website and clicking on the talk of interest.

FGR want to wish you:

A MERRY CHRISTMAS

A MERRY CHRISTMAS

AND

A HAPPY NEW YEAR

Have a great break and stay safe.

Our office is closed from Friday 24th December 2021 and open from Monday 10 January 2022.

Comment from Bart

It is always hard to believe at this time of year that another 12 months seems to have flown by, although what a 12 months it has been. We continue to see restrictions on international movement (both in and out of the country), as well as major challenges within global supply chains. Our log exports have rollercoastered from an all-time high, to a depressed market state in a matter of months and as a country we have been operating with limited certainty for what seems like a large part of the recent 12 months.

In parallel, the Climate Change Commission has released its advice to government and MBIE is progressing a review of the science system, having released its green paper in late October, for consultation. This report and the implications for forestry research should not be underestimated. Crown Research Institutes (CRIs), represent a critically important part of the research, science and innovation (RSI) sector. Unlike Universities, CRIs are mission-led entities and are designed to create impact in key areas of New Zealand’s economy and develop a cutting-edge knowledge base for our significant natural resources. No doubt there are efficiencies that can be gained by “de-cluttering” the science system, removing funding volatility and having improved connectivity across the CRI network, removing duplicated processes where possible. However, Scion is an essential part of the forest research network and is a globally recognised forest research institute, playing a critical role in long-term innovation for our sector. Obviously, no decisions have been made as to how this review will impact the science system. However, given the significance of this review FGR will be engaging in the review process and ensuring that we provide a positive and constructive sector-based view for the importance of a dedicated forestry institute within the RSI system, especially given the critical role that forestry will play in delivering to our climate change commitments. The consultation period ends in March 2022.

Our December newsletter always presents an opportunity to take the time to offer a note of gratitude to those who have contributed to the delivery, leadership and management of FGR’s research programme over the recent 12 months. We operate in a highly collaborative and largely voluntary system, where many farm forestry and industry participants provide their time (and their internet bandwidth) to attend meetings and technical committees, steering groups and governance boards. The impressive results achieved during these exceptional times would not have happened without your collective efforts.

Lastly, I would also like to acknowledge our researchers and research partners; Scion, University of Canterbury, Marlborough Research Centre, Lincoln Bioprotection Centre, Lincoln AgriTech and many other support partners. It has been a challenging 12 months with many uncertainties and ongoing restrictions related to international collaboration and recruitment, however you have shown great adaptability and agility to keep projects on track and continue to progress with minimal disruption.

Let’s hope that 2022 marks a point where things start to get a little easier and we can all enjoy a safe and happy summer with family and friends. Happy holidays.

Bart