Programme Summary

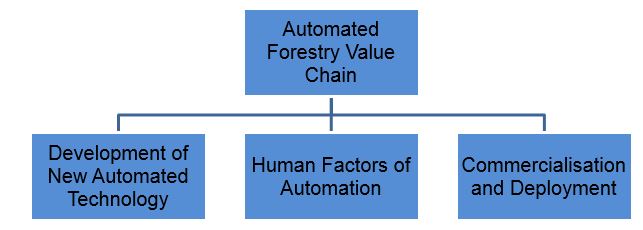

This new FGR programme “Te Mahi Ngahere i te Ao Hurihuri – Forestry Work in the Modern Age” has three major aims: to create value, improve profitability and enhance sustainability across the forestry value chain through automation. It aims to do this by developing a new integrated forestry value chain from harvest to market, incorporating new technologies that will promote both industry and Government interests.

Total investment over the seven years of this programme, from forest industry co-investor cash and in-kind contributions, and from Ministry for Primary Industries (MPI) is $29.36 million, excluding GST. The amount of MPI funding approved is $11.74 million (excl. GST). The cumulative net economic benefits from the programme out to 2030 will total $395 million, from forestry value chain efficiencies and sales of new machinery and equipment. Annual benefits in 2030 will be $100 million p.a.

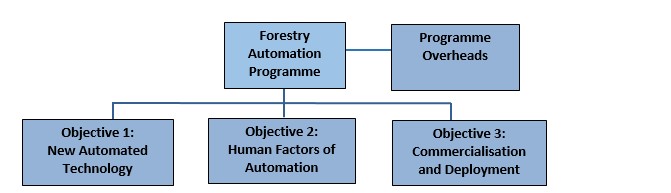

The programme has three project objectives designed around development of new automated technology; human factors of automation and training, and product commercialisation and implementation. The programme plan is to establish five complete sort yard-based systems implemented by individual forestry companies across their forest estates, to develop, prove, customise, introduce, improve and promote the change to a new sort yard system.

Figure 1: Structure of the Programme

Programme Structure

Objective 1: Development of New Automated Technology

Objective 1, New Automated Technology, will design and develop all the equipment and machinery required for the change to the new sort yard system. Initially it will design and build a minimum viable prototype system for implementation by mid-Year 4 of the programme to test and improve the system for future deployment of the subsequent four sort yards (and associated log supply).

The minimum viable system prototype will include:

- Landing products:

- A semi-autonomous grapple and hauler control system

- A log processor–debarker to debark and tag logs as they are manufactured

- A log residue chipper/shredder/grinder attachment (to handle harvesting residues)

- A large capacity log loading grapple (operated with an automatic quick coupler to reduce truck loading delays)

- Sort yard products:

- A mechanical log sorter with full scanning and sorting capabilities (the robotic component will be added subsequently)

- A truck loading gantry to reduce truck loading delays

- A truck load securing system (to ensure security of debarked logs on HPMV trucks)

‘Beta’ prototypes (or pre-commercial models) of each product will be developed as a result of trial and modification of the earlier ‘alpha’ prototypes. These ‘beta’ products will be deployed initially to the harvesting crews supplying the first log sort yard.

Over the next three years (Years 4-6 of the programme) log sort yards #2 – #3 will be established by other Consortium forest owners and contractors. ‘Beta’ prototypes used in these systems will continue to be developed based on the knowledge gained from deployment and field testing of the prototypes in the first log sort yard. In addition to the prototype development costs, field trials will validate the expected economic benefits.

Objective 2: Human Factors of Automation

Objective 2, Human Factors of Automation, will support the development of each product with a focus on human-machine interaction, training to use the new products and the best use of the whole system. There will be initial input to engineering design by the development team and harvesting and log transport contractors as part of the Human Factors programme.

Objective 2 will also include field testing of each product by harvesting and log transport contractors (as part of the Human Factors programme). This Objective will collaborate with manufacturing partners and FGR’s tertiary education and training partners (Competenz, Toi Ohomai Institute of Technology and University of Canterbury School of Forestry).

The aim is to integrate the operator into the machine design, develop initial job design for the new roles, standard operating procedures, training materials for workforce skills & development, recommendations for training programmes and appropriate unit standards for ‘stair-casing’ into new and improved forestry qualifications. This will enable retraining of workers in redundant manual labour roles and also attract new workers from a more diverse demographic to undertake new roles within the logistics system.

Objective 3: Commercialisation and Deployment

Objective 3, Commercialisation and Deployment, will focus on initial deployment of the new products across the first three new log sort yards and commercialisation of the technology.

Initially this Objective will establish the commercial framework for each product. This will be a process of engagement of each manufacturer with a specifier (forest owner) and a user (contractor). This engagement will ensure that market requirements and the product specification are understood and agreed by these parties.

Other Objective 3 activities will include promotion and demonstration of the new system and the individual projects to build market awareness beyond the initial sort yard systems and so facilitate widespread technology adoption.